Busbars can be found in a wide range of electric vehicles, from small passenger cars to large trucks. Different requirements, dimensions and geometries have to be considered in the manufacturing process of these vehicles. Busbar machines from WAFIOS cover a broad product range. Read more…

Category: E-Mobility Engineering

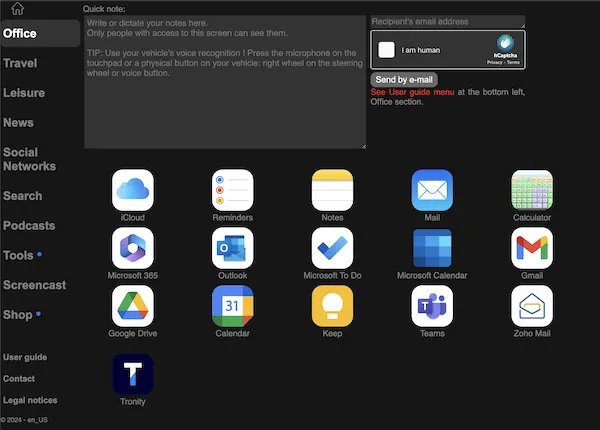

Coreless technology shrinks current sensor

Melexis has used a digitally controlled, coreless technology that shrinks the size of a current sensor, writes Nick Flaherty.

The MLX91235 sensor eliminates the need for a ferromagnetic core, enabling the measurement of larger currents flowing through external primary conductors, including busbars. Read more…

innolectric unveils CEC flexible charging platform

Innolectric has rolled out the Compact Efficient Charger (CEC) platform, designed to simplify and optimise the charging process for EVs.

With its power density of 2.0 kW/L, the CEC is compatible with major AC and DC charging standards. Read more…

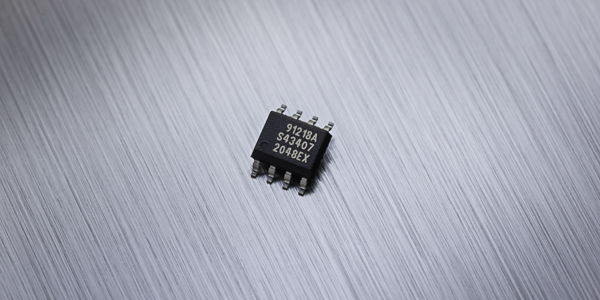

Analysis finds Altilium’s CAM outperforms virgin mined materials

Altilium has announced the results of research by Imperial College London, revealing that its recycled cathode materials (CAM) match and outperform virgin mined materials – a critical milestone in the bid to meet net-zero targets. Read more…

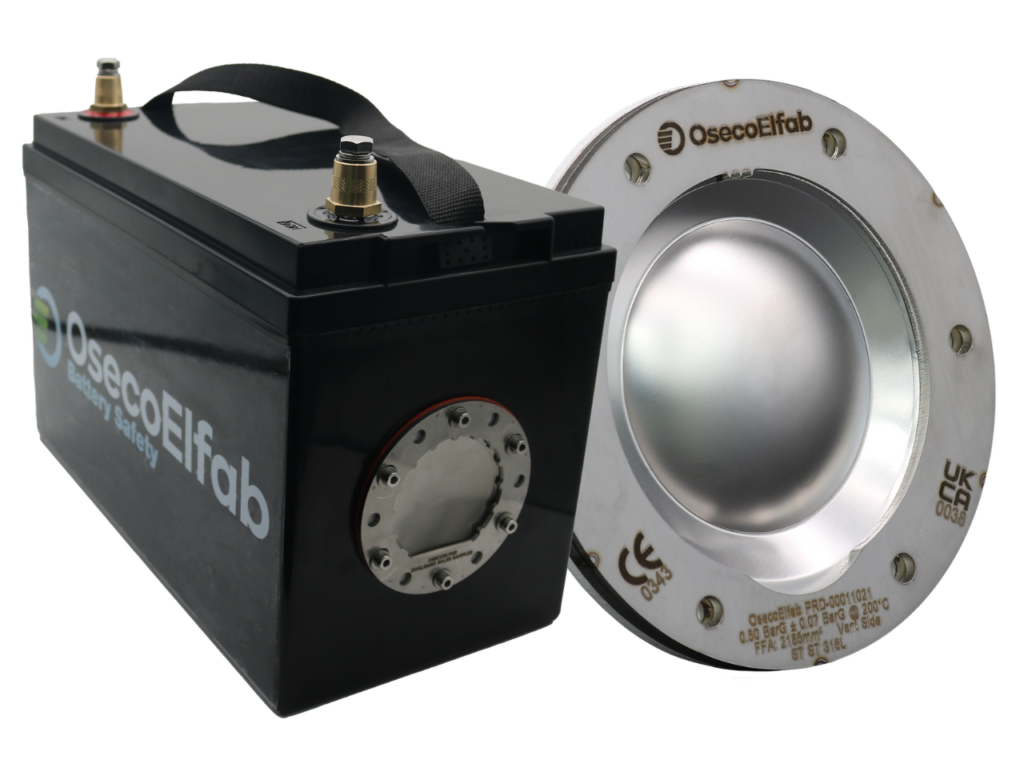

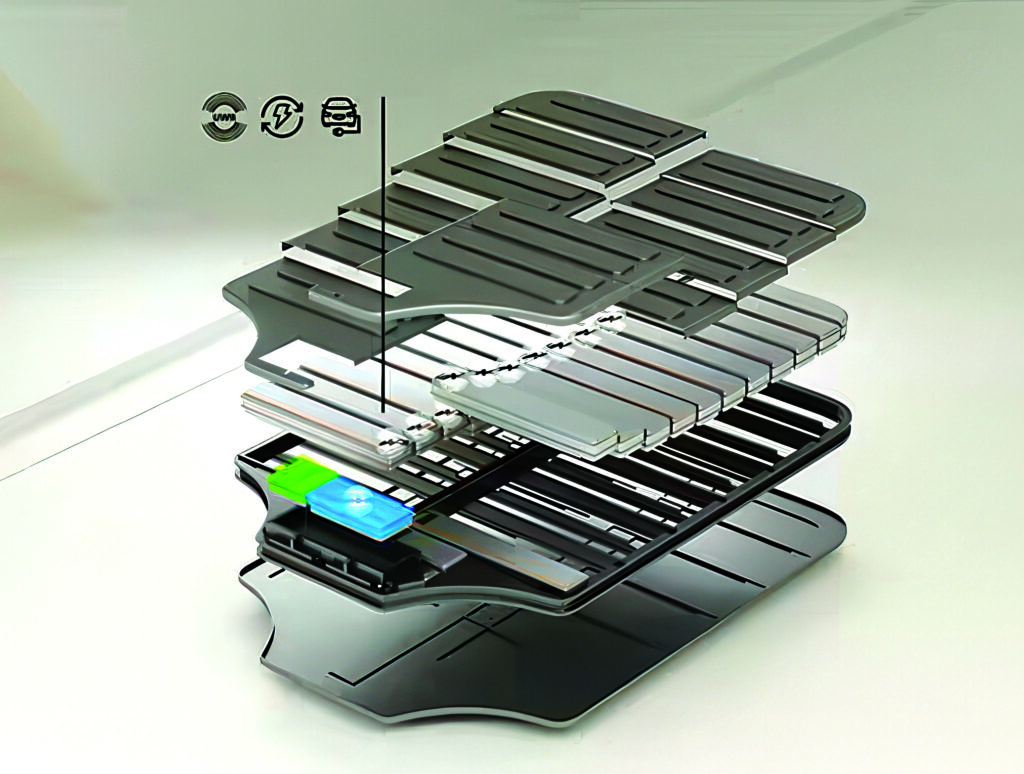

OsecoElfab offers pressure relief for Li-ion batteries

OsecoElfab has launched a portfolio of pressure-relief solutions designed for lithium-ion battery applications in the e-mobility sector, marketed under the OE Lion brand.

The specialised rupture discs support custom battery design, enabling manufacturers to create safer, simpler and more cost-effective Li-ion batteries. Read more…

Littelfuse rolls out new series of dual-circuit tactile switches

Littelfuse has unveiled the C&K Switches KSC2 KSC Dual Circuit Technology (DCT) series.

The latest addition to its innovative tactile switch series offers a 3.5 mm actuator height, which is lower than the KSC4 DCT at 5.2 mm. This allows it to fit into tighter spaces, providing greater design flexibility. Read more…

Additive Drives uses injection-moulded copper

Additive Drives has developed an injection-moulded copper process for the next generation of electric-drive busbars, writes Nick Flaherty.

The development combines the best of two worlds: specialised design and mass production.

Additive Drives is using the process for busbars with printed, conventional or injection-moulded parts in copper and plastic. Read more…

Dürr, Cellforce and LiCAP team up for dry electrode tech

Dürr Systems and LiCAP Technologies are working together to revolutionise the production of battery cells, traditionally reliant on wet coating, with the sustainable Activated Dry Electrode technology. Read more…

Yokogawa releases high-voltage, wide-bandwidth differential probe

Yokogawa Test & Measurement Corporation has released its PBDH0400 series differential probe with a maximum input voltage of 2000 V and a frequency bandwidth of 400 MHz.

The probes can deliver the measurements required for developing the next generation of higher speed power devices. Read more…

Bi-directional onboard chargers get current sensor

LEM has developed a current sensor for transformerless, bi-directional, onboard chargers (OBCs), writes Nick Flaherty.

The automotive-grade, residual current monitoring (RCM) sensor is the first of its kind for bi-directional OBCs with ASIL B safety rating. Read more…

Brady sensors offer battery temperature warning

Electric vehicle (EV) lithium battery fires in facilities such as factories, warehouses, parking structures and ships, though rare, are lethal and destructive when they happen, but remote monitoring of battery temperature can provide a timely warning of a developing problem, writes Peter Donaldson. Read more…

Recycling cathode materials using galvanic corrosion

Researchers in Korea have developed a cost-effective and eco-friendly technology for recycling cathode materials from spent lithium-ion batteries through a simple process within an existing cell without the need for disassembly, writes Nick Flaherty. Read more…

ZF offers three-step service with new Bike Eco

With the market launch of its ZF Bike Eco System, ZF has given details of its three-step service and training concept, which, it says, guarantees minimal effort for manufacturers, dealers and customers when it comes to servicing and retrofitting. Read more…

Capacitorless solid-state power filter for single-phase DC-AC converters

Researchers in the US have developed a solid-state filter for power converters that does not need a capacitor.

Capacitors are one of the main points of failure in an e-mobility power system, responsible for 30% of failures in power electronics. Read more…

Henkel’s Battery Engineering Center

Primarily known as a producer of chemical solutions across a number of different industries, German multinational group Henkel has launched a Battery Engineering Center (BEC) within its Inspiration Center Duesseldorf, aimed at providing strategic partnerships to OEMs and battery manufacturers (and others in the e-mobility space) through the BEC and its services and products there. […] Read more…

Magnesium electrolyte sparks next-generation battery design

University of Waterloo researchers have made a key breakthrough in developing next-generation batteries made of magnesium instead of lithium.

When the idea to create batteries using magnesium was first shared in a seminal academic paper in 2000, the novel design didn’t provide enough voltage to compete with lithium-ion batteries. Read more…

Hyundai Mobis tackles overheating during fast charging

Hyundai Mobis (KRX 012330) announced on 18th that it has developed a new battery cell cooling material to prevent battery overheating during ultra-fast charging of electric vehicles. Read more…

Wireless BMS built with ultra-wideband tech

NXP Semiconductor has developed the first battery management system (BMS) using ultra-wideband (UWB) technology, writes Nick Flaherty.

Using wireless connections between battery cells and the BMS in a pack simplifies assembly and enables better energy density. Read more…

Trio of auto-grade power modules offer 300 combinations

Vicor has developed three automotive-grade power modules that can be used in 300 combinations in 48 V EV systems, writes Nick Flaherty.

They cover a bus converter from 800 V to 48 V, an unregulated 48 V to 12 V converter and a regulated 48 V power-supply module. Read more…

MW-class motor electric aircraft takes off with 3300 bhp

Wright Electric has finished assembling its second-generation megawatt-class motor, the WM2500, writes Nick Flaherty.

The motor has been built with support from the US ARPA-E ASCEND research programme and NASA, and it is spinning freely after being assembled in December. Read more…