Honda Motor Co has unveiled the demonstration production line for all-solid-state batteries in Sakura City, Tochigi Prefecture, Japan. It plans to begin battery production on this line in January 2025. Read more…

Category: E-Mobility Engineering

Altilium achieves milestone in EV battery recycling

Altilium has announced a major breakthrough in the development of the UK’s only domestic supply of sustainable, low-carbon battery materials, with test results confirming its recycled cathode active materials (CAM) are comparable to commercial materials. This positions recycled materials as a competitive alternative to mined sources. Read more…

Aluminium busbar process cuts costs and weight

brandgroup, a medium-sized, German company, is to develop and manufacture innovative and efficient springs, spring assemblies and wire-forming parts using a process for the manufacturing of aluminium busbars with high-cross sections up to 300 mm2 in the automotive charging path to cut weight and cost, writes Peter Donaldson. Read more…

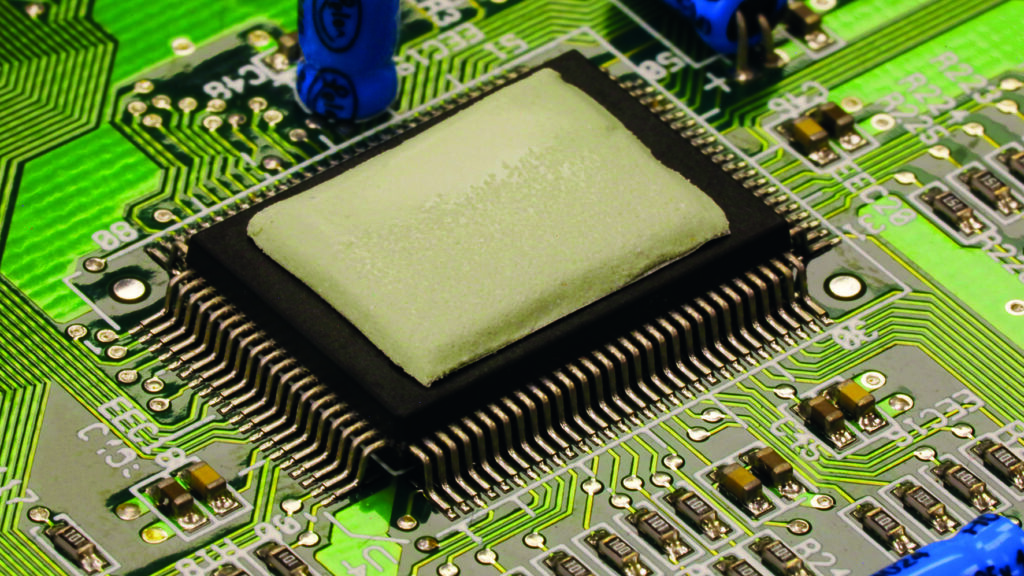

Parker Chomerics thermal gap pad offers low oil bleed

The Chomerics division of Parker Hannifin Corporation has introduced the THERM-A-GAP PAD 80LO, a high-performance thermal gap pad with low oil-bleed and migration.

The RoHS-compliant pad features a high-tack surface that reduces contact resistance, an operating temperature of -50 C to 200 C and a UL 94 V-0 flammability rating. It is also electrically isolating. Read more…

First Schottky diode for high-voltage DC links

Infineon has created the first 2000 V Schottky diode for high-voltage (HV) DC link designs, writes Nick Flaherty.

The CoolSiC 2000 V G5 is the first discrete silicon-carbide diode with this breakdown voltage, making it suitable for DC links up to 1500 V with current ratings from 10-80 A. This makes it ideal for higher DC-link voltage applications. Read more…

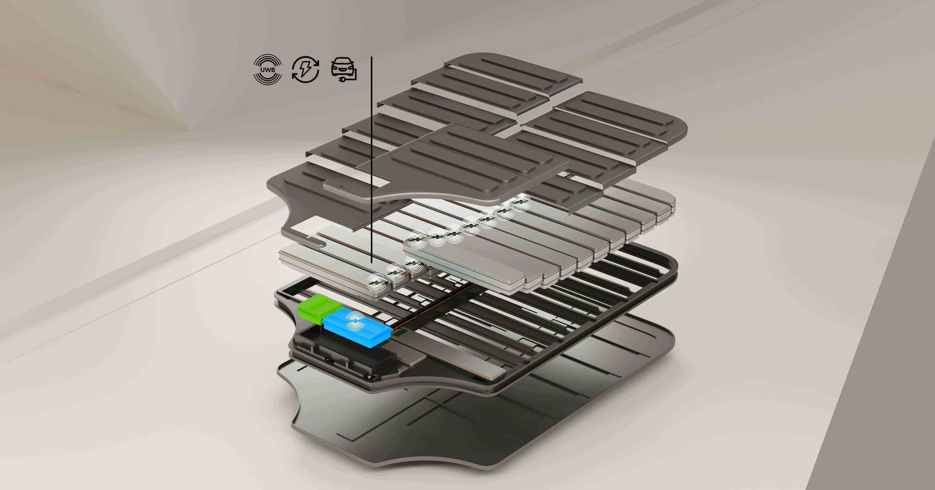

NXP unveils industry-first ultra-wideband wireless BMS

NXP Semiconductors’ Ultra-Wideband (UWB) wireless battery management system (BMS) simplifies EV assembly, enables higher energy density, and decouples mechanical and electrical development for faster time to market. Read more…

ACP Systems automates jelly roll production in Germany

To reduce reject rates, improve quality and develop innovative designs, an automated and digitised production line for cylindrical battery cells has been developed at the Center for Digitalized Battery Cell Manufacturing (ZDB) at Fraunhofer IPA in Germany. Read more…

Temperature-responsive material performs well against thermal runaway

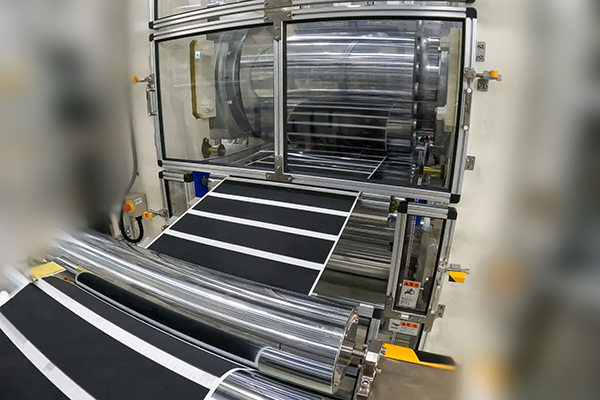

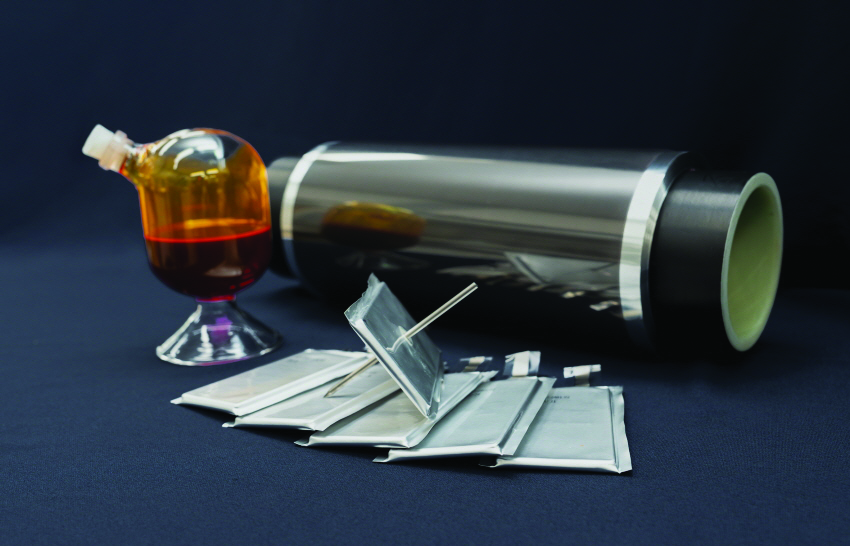

LG Chem has developed a temperature-responsive material that can suppress thermal runaway and be manufactured in a high-volume, roll-to-roll process, writes Nick Flaherty.

The Safety Reinforced Layer (SRL) is a composite that can be as thin as 1 μm. It is placed inside a battery cell between the cathode layer and the current collector, with the aluminium foil acting as the electron pathway. Read more…

Electrode-to-pack

In the quest for energy density in EV batteries, cell-to-pack (CTP) architectures represent an approach that increases the proportion of active materials by eliminating modules, and their associated structure and interconnections. Read more…

Onboard chargers

Nick Flaherty examines how designers are making OBCs more powerful, faster and lighter.

The onboard charger (OBC) market is changing with increasing power levels for faster operation and the need for lighter systems that can be integrated with the other vehicle components. Read more…

Battery dielectric protection

Peter Donaldson examines multi-function dielectric materials for battery systems.

Dielectric protection materials are critical in EV battery systems, where they serve to insulate components from one another, reduce the risks to technicians working on them, and often also contribute to structural strength and thermal management. The wide variety of materials and forms present various advantages and limitations, making selection a complex process that is increasingly focused on the specific demands of each application. Read more…

Cell ageing characteristics

Modelling battery cells at end of life is becoming more popular for key reasons, as Nick Flaherty reports.

Accurate prediction of battery lifespan is crucial for e-mobility and involves a variety of test approaches, from thermal measurements to transmission electron microscopes. Assessing how a cell delivers power when required and how it is charged provides insights into its lifetime. Read more…

Halevai electric boat

Halevai is on a mission to redefine the recreational marine market, combining an electric powertrain with a trimaran hull, reports Will Gray.

It might look like a relatively ordinary recreational day cruiser, but in an industry that is traditionally as slow moving as a heavily loaded tanker, the design of Halevai’s model2050 – which pairs an innovative but highly standard electric powertrain with an ultra-efficient trimaran hull – places it firmly in the ‘ground breaker’ category. Read more…

In conversation: Dr Keon Woo Lee

Peter Donaldson chats to a leading battery expert, who says innovation is all about winning against the things you can trade off.

In a rapidly evolving EV landscape, the quest for advanced battery technologies remains at the forefront. Dr Keon Woo Lee leads Henkel’s Fuel the Future Team and Engineering and Advanced Testing Team at the newly opened Battery Engineering Center (BEC) within the Inspiration Center Düsseldorf, Germany. Read more…

ICEBreaker hydrogen HGV

Two companies have teamed up to build a hydrogen-powered HGV using a fuel-cell powerplant, as Peter Donaldson reports.

Spearheaded by powertrain energy-management specialist Viritech, Project ICEBreaker has built a hydrogen-powered heavy goods vehicle (HGV) using a fuel-cell power plant, focusing on minimising the weight penalty compared with internal combustion engine (ICE) vehicles. Read more…

IONETIC slashes EV battery pack development time and costs

IONETIC has unveiled Arc, which it refers to as a world-first, software-accelerated, AI-supported development system that delivers multi-million-dollar savings in battery development costs and halves time-to-market for custom packs. Read more…

Parker Chomerics to show thermal interface materials at electronica

The Chomerics division of Parker Hannifin Corporation will present a trio of new thermal interface materials at Electronica 2024, staged on November 12-15 in Munich, Germany.

Exhibiting at booth B3.236, the innovations on show will include new thermal, cure-in-place, gap-pad and dispensable gel products. The company is also planning to announce the launch of a rapid sampling and prototyping service. Read more…

Faster heavy EV production

A purpose-built high voltage modular cable assembly (mCAY) has been developed to speed up production of heavy duty electric vehicles, writes Nick Flaherty. It can be said that many vehic manufacturers focus on the direct costs of their solutions, without paying enough attention to indirect production costs such as assembly, test and production equipment, or even reworks. Read more…

comemso aims to simplify charging analysis

Comemso has launched comframe, a platform designed to simplify and streamline the analysis and testing of various e-mobility applications.

“Our aim was to design the essential features in a way that allows beginners to start testing and analysing right away, and provides experts with detailed measurement and analysis capabilities,” said Anita Athanasas, CCO of Comemso. Read more…

Charging forward with polyphase

A polyphase wireless power transfer system has achieved a record 270 kW charging rate, writes Nick Flaherty. Researchers in the Power Electronics and Electric Machinery Lab at the Oak Ridge National Laboratory (ORNL) in the US successfully demonstrated the first 270 kW wireless power transfer to a Porsche Taycan at the end of a three year project with Volkswagen. Read more…