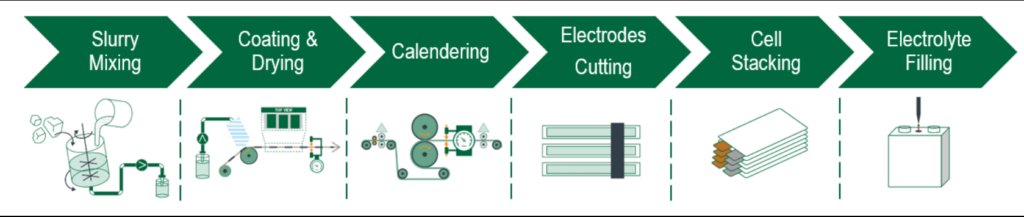

Battery anodes and cathodes are typically made from slurries of active chemical powders and supporting substances such as binders and solvents applied to foil substrates, before being dried, cut and combined into ‘jelly rolls’ or laminates to form the core components of cells (writes Peter Donaldson).

The process inevitably generates dust and vapours that are variously toxic, explosive or polluting. Along with other contaminants, they can also degrade battery safety, performance, reliability and cycle life. Read more…

How Camfil cleans up the battery production process

Bookmark the permalink.